ClearImage®

ClearImage® non-magnetic interconnect solutions for imaging applications

KS Docking

KS Docking connectors hold the utmost reliability when transmitting data from remote locations

L & N Series

L & N Series high density module rack & panel connectors can be configured with a large number of various contacts in a single frame

D0 Series

The D0 series simple and reliable solution for quick connections

Hypergrip®

The Hypergrip® user configurable connectors

Critical Connections in the Medical Market

Smiths Interconnect has delivered a high-reliability interconnect solution to the medical industry where integrity and reliability is essential to the well-being of a patient.

Applications Include:

- Implantable Devices

- Magnet Resonance Imaging

- Digital Imaging

- Electrophysiology Catheters

- Defibrillators

- Patient monitoring equipment

- Ultrasound Equipment

KVPX Series

VITA 46 and 48 High Speed, High Density, Rugged Interconnects

HTT Contacts

HTT contacts high temperature versions of ultra-reliable Smiths Interconnect hyperboloid technology.

PC/104+

PC/104+ board stacking connectors

KA Series

KA versatile printed circuit board connectors available in 2, 3, 4 & 5 row options

KFT Series

KFT Series miniature low profile, dual row in-line stacking interconnects

L & N Series

L & N Series high density module rack & panel connectors can be configured with large number of various contacts in single frame

Platform Examples:

- Commercial Aircraft

- Combat Vehicles

- Future Soldier Systems

- Military Aircraft

- Missiles / Torpedos

- Marine Vessels

- UAVs

Application Examples:

- Avionics / Vetronics

- Guidance, Navigation & Control

- High Power

- Radar and Communications

- High Temp (up to 440°C)

- Power Distribution

- Test & Instrumentation

Mission Critical Interconnects

for Military, Defense and Aerospace

Smiths Interconnect is a global leader in the design, manufacture and supply of high performance interconnect solutions to the world’s leading commercial and military aerospace manufacturers of various naval, land and air systems and applications. From commercial airlines to new generation military aircraft, SMITHS INTERCONNECT interconnect solutions are used extensively on all Mil / Aero systems where reliability is absolutely mandatory. The interconnect system in Military and Aerospace applications must be able to withstand the rigors of environments where extreme shock and vibration as well as heat, dust, moisture and chemicals are prevalent.

HTT Contacts

HTT contacts high temperature versions of ultra-reliable Smiths Interconnect hyperboloid technology.

PC/104+

PC/104+ board stacking connectors

KA Series

KA versatile printed circuit board connectors available in 2, 3, 4 & 5 row options

KFT Series

KFT Series miniature low profile, dual row in-line stacking interconnects

VME 64x

VME64x VITA approved, high level connector solution for embedded bus architecture technology.

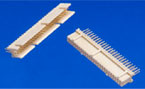

L & N Series

L & N Series high density module rack & panel connectors can be configured with a large number of various contacts in a single frame

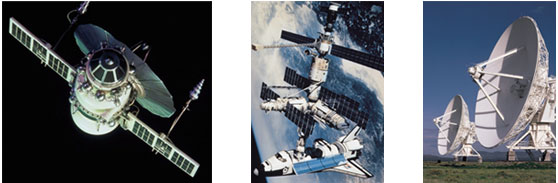

Reliability in Space

From planetary rovers to space station, Smiths Interconnect meets the constantly increasing demands of all space applications. Their connectors have been put through and exceeded the rigorous testing of NASA involving extreme environmental conditions, which includes thermal excursions, corrosive atmospheres, excessive shock & vibration, and contact engagement and separation cycling. NASA subsequently issued an addendum to EEE-INST-002 that states the required use of “Basket of Wires” Smiths Interconnect technology and prohibits the use of tuning-fork and press-fit connectors in future space missions, given their inability to perform in extreme thermal environments.

The interconnect system in Space applications must be able to withstand the harshness of environments where severe shock and vibration, corrosive atmosphere, and intense thermal deviations are prevalent. SMITHS INTERCONNECT high reliability connector solutions provide insurance of continuous connection within such extreme conditions. The legendary Smiths Interconnect' technology is widely known for its resistance to fretting and immunity to severe shock and vibration.

Platform Examples:

- Satellites

- Manned Space Vehicles

- Planetary Rovers

- Planetary Probes

- Radar and Communications

HTT Contacts

HTT contacts high temperature versions of ultra-reliable Smiths Interconnect hyperboloid technology.

KA Series

KA versatile printed circuit board connectors available in 2, 3, 4 & 5 row options

KFT Series

KFT Series miniature low profile, dual row in-line stacking interconnects

L & N Series

L & N Series high density module rack & panel connectors can be configured with a large number of various contacts in a single frame

Industrial / Test & Measurement

Smiths Interconnect superior Smiths Interconnect® Technology provides the reassurance of a strong consistent connection. Eliminate significant production downtime, loss of critical data, expensive maintenance repairs, and damage to product reputation with Hypertronics ultra reliable interconnect systems.

Reliable interconnections in Industrial applications must be able to withstand the rigors of environments where heat, dust, moisture, shock and vibration, and chemicals are prevalent. Our knowledge of electrical connectivity has developed out of our vast experience obtained within these industries and allows for us to manufacture a superior interconnect solution.

The Smiths Interconnect technology is known for 100,000+ mating cycles, immunity to shock and vibration, and providing a reliable and consistent connection in the harshest environments.

Applications Include:

- Test & measurement

- Portable data collection

- Telecommunications

- Rail traction

- Heavy machinery

- Robotics and factory automation

- Industrial equipment

- Pipeline inspection

HTT Contacts

HTT contacts high temperature versions of Hypertronics’ ultra-reliable Smiths Interconnect hyperboloid technology.

KA Series

KA versatile printed circuit board connectors available in 2, 3, 4 & 5 row options

KFT Series

KFT Series miniature low profile, dual row in-line stacking interconnects

L & N Series

L & N Series high density module rack & panel connectors can be configured with a large number of various contacts in a single frame

Smiths Interconnect Technology in Oil & Gas Pipeline Inspections

The superior performance of Smiths Interconnect connectors along with the capability to customize solutions has made Smiths Interconnect the preferred supplier of interconnects for extreme environments. Experiences gained over the years in all business sectors to improve the engineered connector solutions for our customers have migrated to the oil & gas pipeline inspection industry. Intelligent Pipeline Inspection Gauges (PIGs) operate in extremely harsh conditions while moving down an oil or gas pipeline. PIGs encounter shock and vibrations, debris, temperature extremes and other environmental challenges, all of which can potentially compromise data and system integrity.

The Smiths Interconnect technology is known for 100,000+ mating cycles, immunity to shock and vibration, and providing a reliable and consistent connection in the harshest environments, which makes them ideal solutions.

Possible Solutions:

- Eradicate costly downtime

- Prevent electrical discontinuities

- Reduce power consumption

- Eliminate assembly problems

- Lessen expensive repair costsy

- Mitigate design challenges